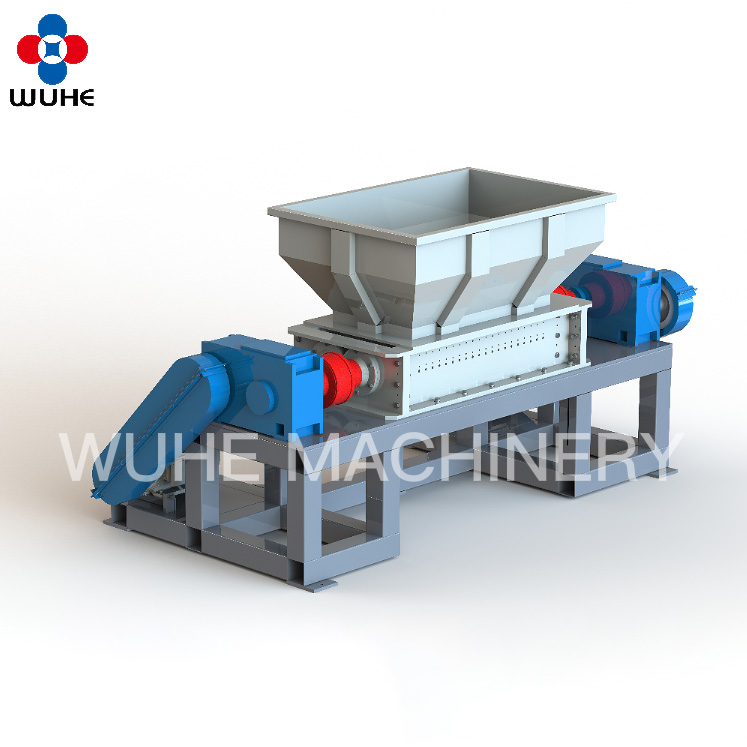

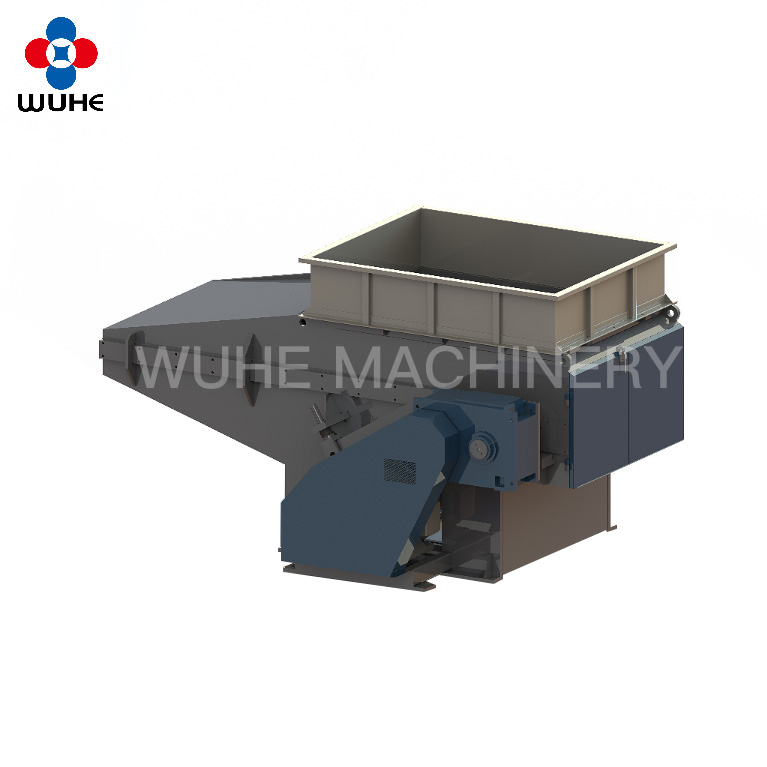

MPS Pipe Shredder Machine Unit

Specification

In recent years, with the rapid development of large-diameter PE plastic pipes, how to effectively recover PE waste pipes and machine head materials in the production process has become a problem for many pipe manufacturers to solve. Some manufacturers rely on purchasing expensive or high-power and inefficient equipment to recover, resulting in high investment costs. Some manufacturers use manual sawing of waste pipes into small pieces before crushing, resulting in extremely low recovery efficiency. How to economically and effectively recover large-diameter PE plastic waste has become a key research topic for PE plastic manufacturers. The emergence of a large diameter pipe shredder effectively solves this problem. The motor drives the gearbox and the main shaft to rotate, and a high-strength alloy knife is installed on the main shaft. The knife is a square knife with four corners. One corner of the knife can contact the material, and the purpose of shredding is achieved through shaft rotation. The shredded plastic can be directly transported to the crusher through a conveyor belt for secondary crushing work, The entire working process can be controlled by PLC, which is easy to operate and saves labor.

Summary:

●Diameter of pipe ≤1200mm

●Length of pipe ≤6m

●Output ≥1000kg/h

Specification:

BPS1500 pipe shredder

|

Model |

MPS-600 |

MPS-800 |

MPS-1000 |

|

Inlet dimension(mm) |

500*500 |

720*700 |

850*850 |

|

Motor power(Kw) |

22 |

37 |

55 |

|

Rotating speed(rpm) |

85 |

78 |

78 |

|

Rotor diameter(mm) |

300 |

400 |

400 |

|

Rotor width(mm) |

600 |

800 |

1000 |

|

Rotary blade |

22 |

30 |

38 |

|

Fixed blade |

1 |

2 |

2 |

|

Hydraulic power(Kw) |

1.5 |

2.2 |

3 |

|

Biggest pipe(mm) |

Ф500*2000 |

Ф630*2000 |

Ф800*2000 |

| Mobile hopper

|

● Vertical hopper, easy to load the entire section of pipe ● Linear rail movement ● Oil free bearing ● Hydraulic tightening |

| Body frame | ● Through type box design, high strength ● CNC processing ● Heat treatment processing ● Box: 16Mn |

| Rotor | ● Blade optimization layout ● Overall tempering heat treatment ● CNC processing ● Blade material: SKD-11, used on all sides |

| Hydraulic trolley | ● Roller type support ● Pressure and flow regulation ● Propulsion pressure: 3-5 Mpa |

| Drive | ● Hard tooth surface reducer ● Elastomer efficient shock absorption device to protect the reducer and power system ● SPB belt drive |

| Control system | ● PLC automatic control system |