PP Woven fabric bag recycling pelletizing line

Main parameter

Conveyor + metal detector

● It matches with compactor to realize automatic control.

● Metal detector is on the middle of the belt, to detect the metal from the materials, customized China brand or German brand.

Spiral Feeding hopper

● As the woven bag itself is light and foamy, the use of spiral feeding can effectively prevent the bridging of woven material, which can be better fed into the screw to improve the output.

Extruder machine

● Single screw extruder with Efficient air exhausting to improve the material quality, It equipped with a special design of the barrel and screw and single screw exhaust system, can ensure high yield.

Vacuum air exhausting system

● Efficient air exhausting to improve the material quality.

● Exhausting style: vacuum water filter.

● Vacuum room: special design.

● Vacuum cover plate: aluminum alloy.

● Vacuum tube: temperature and pressure resistance rubber tubes.

Single stage granulation and double stage granulation are determined by the material. Below are the detailed information of the second stage extruder.

Baby extruder

● Two-stage extruder can more effectively discharge water and impurities from materials, and the quality of particles is better.

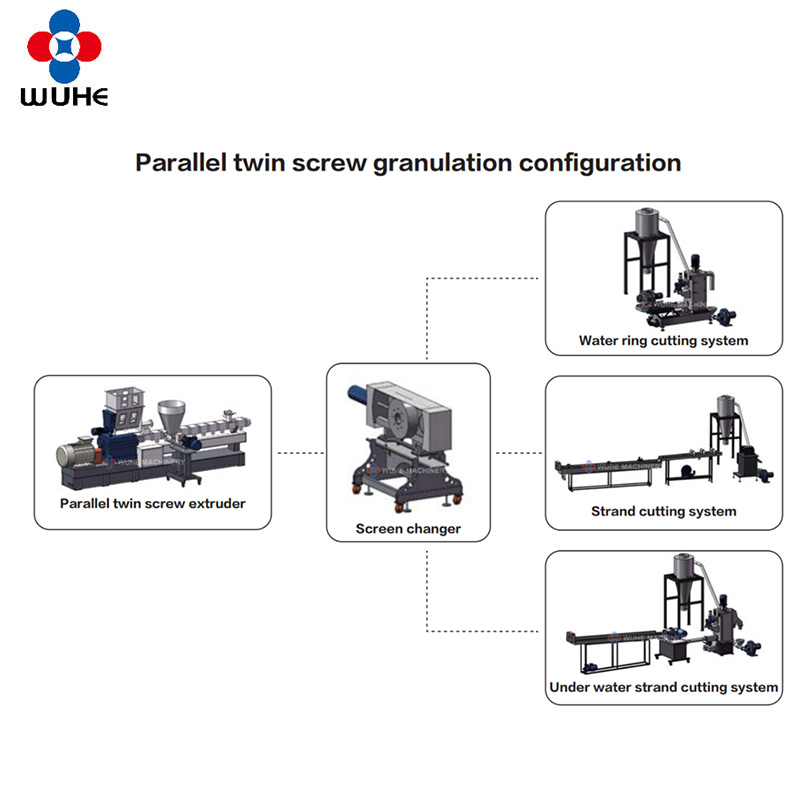

Screen changer

● Different screen changers meet the needs of different customers.

We mainly have two modes of pellets cutting system for these kind materials:

1. The water ring cutting system.

2. The strand cutting system.

Based on different material characteristics, we will recommend different cutting methods.

1. Water ring cutting system

● The cutting system adopts extrusion die head water ring to cut, which can ensure the perfect appearance of particle.

Centrifugal dewatering machine

● This machine have many advantages, such as high degree of dehydration, low power consumption, high efficiency, high degree of automation, and greatly reduces labor intensity. Dehydration is clean, and it is also can wash off the micro sand and small sundries in the pla.

2. Strand cutting system

● For some materials with high viscosity, such as PP, we recommend using a strip cutting method.

● Air pipeline drying

The water in pellets surface is evaporated through air pipeline conveying principle, and it transports the dried pellets to the collection hopper, then for follow-up treatment.

Electrical control system

● PLC automatic control

Material diagram