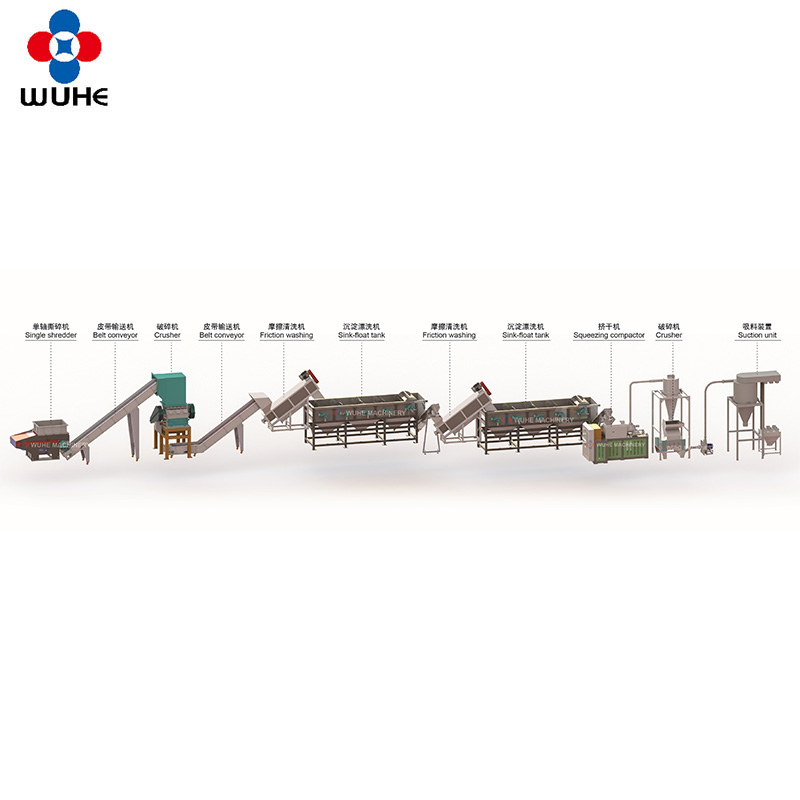

PE,PP bottle barrels hard plastics washing line (dewater dryer machine)

Main parameter

Belt conveyor

● Function: rubber belt conveying the materials to the next process.

Shredder machine

● Function: It is applicable to the recovery of a variety of bulk solid materials, refractory materials, irregular plastic containers and plastic barrels, tubes, films, fibers, paper etc. Spindle speed is 45 ~ 100 rpm/min, which has stable work and low noise.

Crusher machine

● This machine adopts the steel structure, casting steel frame, steel cutting tools, which avoids splitting.

● Using movable sieve can conveniently assemble and disassemble and conveniently clean and change network.

● Feeding door uses insulation sandwich to reduce noise and improve the working environment.

● The feeding hopper adopts protection switch to protect the safety of operating person.

High speed friction washer machine

● WH series high-speed friction washer is widely for washing recycled waste plastic, especially for plastic bottles, sheets and film, etc.

● Part in contact with materials in high-speed friction washer is made of stainless steel, stainless and no pollution to the washed materials. Full automatic design needs no adjustment during operation.

● Principle: Separated spiral screw keeps flakes from going out immediately but rotating on a high-speed basis. Therefore mutual strong frictions between flakes and flakes, flakes and screw can separate flakes from dirty things. The dirty will be discharged from sieve holes.

Screw loader machine

● Function: using screw conveying the materials to the next process.

Floating washer machine

●WH series floating washer tank is washing and separate PE films&PP woven bags from the dust materials.

●The machine is made up of frame, washing tank, stirring tool and conveying system.

●Washing tank: made of stainless steel, the wall board contacted with water is made of stainless steel.

●Stirring tool: made of stainless steel to convey and wash material, it is used to scatter the material, and enlarge the contact surface of material and water, and push forward the material and put the material under the water and has the immerge effect.

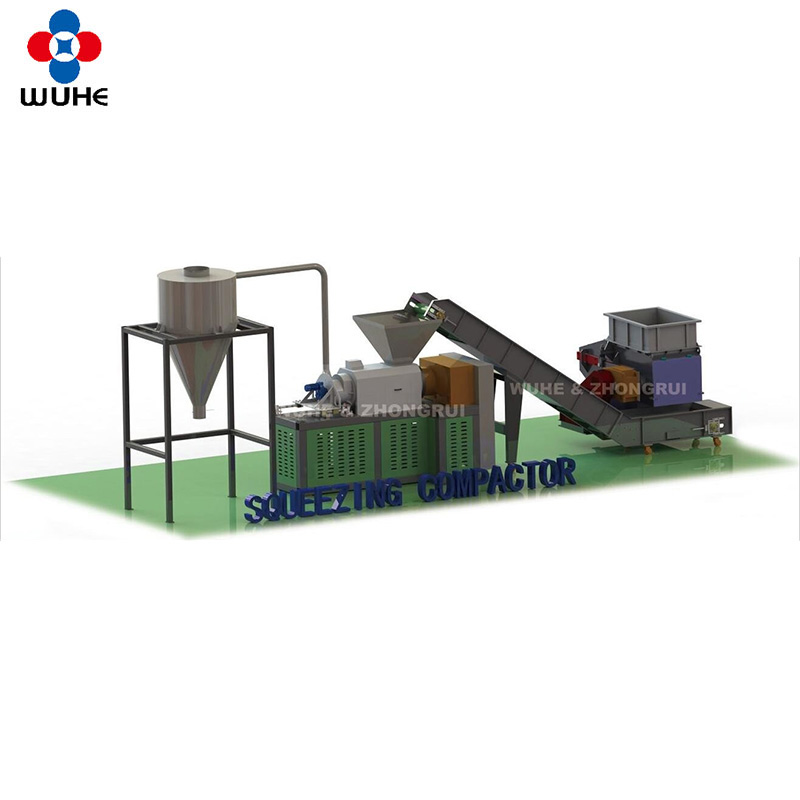

Dehydrator machine

● Part in contact with materials of WH series centrifugal dryer is made of stainless steel to keep conveyed materials from pollution. Full automatic design needs no adjustment during operation.

● Principle: Materials are conveyed into centrifugal dryer by spiral loader.

● Separated spiral screw keeps flakes from going out immediately but rotating spirally on a high-speed basis. Therefore centrifugal force can separate water from materials. The materials will be discharged from sieve holes.

Dryer machine& air-sending machine

● Function: Use a fan to dry the clean flakes from the dehydrator with dry air to achieve further drying.

Electrical control system

● PLC automatic control